Introduction: Globally, aneurysms affect 2-5% and afflict millions in the U.S., presenting significant health threats due to their high rupture rate that can lead to death. Conventional aneurysm coil treatments grapple with problems such as adverse bodily reactions, biocompatibility issues, and a recurrence risk of about 20%, with complete occlusion failures in 10-15% of patients because of geometrical incompatibility. Although 4D-printing technology creates new prospects for creating custom biomedical implants, finding suitable materials remains an ongoing challenge.

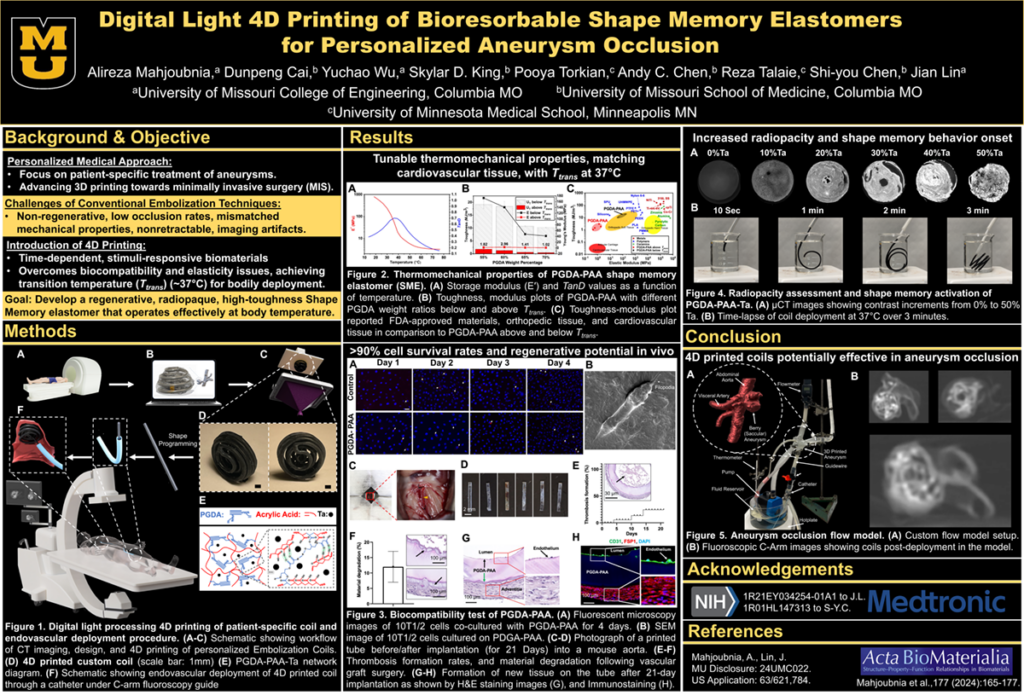

Methods: Utilizing digital light 4D-printing, a shape memory elastomer (SME) was engineered by synthesizing glycerol dodecanoate acrylate prepolymer (pre-PGDA) with an acrylic acid monomer to establish a crosslinked Poly(glycerol dodecanoate acrylate)-Polyacrylic acid (PGDA-PAA) structure. This development included biocompatibility testing and vascular grafting experiments. A personalized coil was then crafted and applied to a 3D-printed aneurysm flow model derived from a real patient.

Results: At a precision of ~150 microns, the 4D-printed SME can recover its shape when exposed to body temperatures, thereby imitating the mechanical properties of soft tissues. Tests showed that the material supported over 90% cell growth and improved cell adherence. In vivo vascular grafting experiments demonstrated regeneration of the aorta after implantation. This versatility, combined with the material’s capacity for absorption, suggests it could potentially be replaced by natural tissue. Endovascularly deployment of 4D-printed coils within a flow model endorses this minimally invasive technique. The inclusion of tantalum in the coils significantly improves their radiopacity, which aids in the exact positioning and tracking of the coils after insertion, thus enhancing the effectiveness of the procedure.

Impact: This advance in 4D-printing highlights the PGDA-PAA elastomer’s biocompatibility, biodegradability, mechanical properties, making it an excellent choice for implantation. Fabricating patient-specific embolization coils represents a proof of concept that 4D printed coils flawlessly deploy in situ, reducing complications after surgery.

Organization: University of Missouri – Columbia

Mahjoubnia A, Cai D, Wu Y, King SD, Torkian P, Chen AC, Talaie R, Chen S, Lin J